Product Introduction

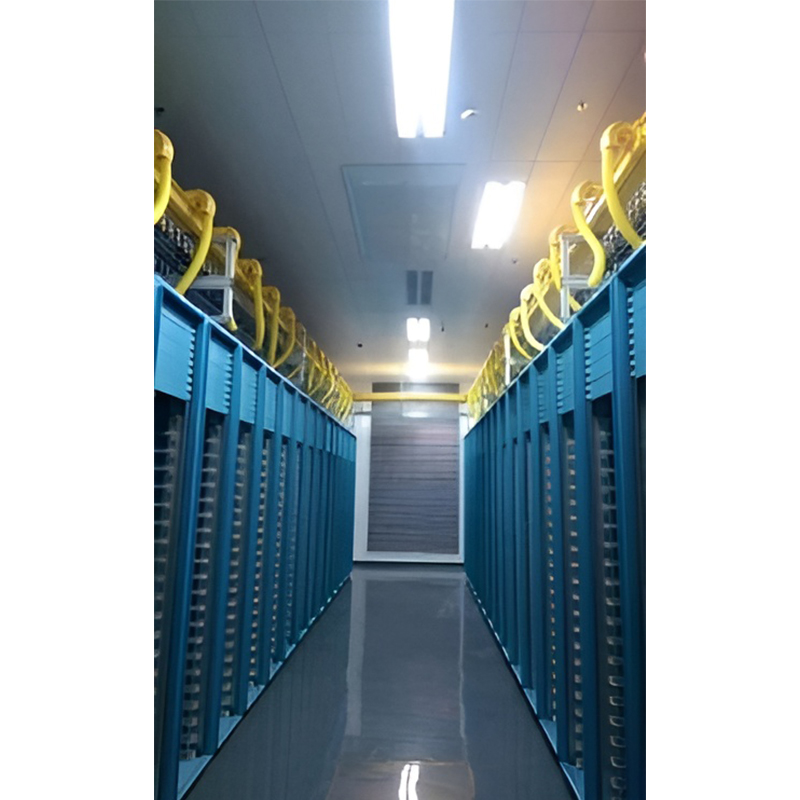

The establishment of the hot air channel closure system meets the increasing heat dissipation demands of data centers. It addresses localized hot spots within the server room, preventing the direct mixing of cold and hot air and reducing the waste of cooling energy. The cabinets are arranged in a "back-to-back" configuration, creating a cold aisle throughout the server room. Cold air flows through the equipment, resulting in hot air that is expelled into the "hot air channel" at the back of the two rows of cabinets. This hot air is then returned to the air conditioning system, ensuring smooth airflow and energy flow throughout the entire server room, enhancing the efficiency of precision air conditioning and further improving cooling performance.

The hot air channel closure system is particularly beneficial in regions with lower average annual temperatures, allowing for natural ventilation for most of the year, thus reducing cooling costs.

Features:

High Return Air Temperature: Enhances the cooling efficiency of the air conditioning system.

Increased Overall Cooling Area: During cooling interruptions, temperature rise can be delayed.

Shared Cooling Capacity: In the event of a failure or insufficient cooling from one air conditioning unit, other units can be utilized to compensate..

1. Modular Design: The hot air channel closure system consists of modular components, with two cabinets on each side forming a single module. Each module can be easily installed or removed, allowing users to add, remove, or relocate cabinets as needed.

2. Safety Features: Each channel is linked to the fire alarm system. If a fire is detected in the server room, the channel will automatically open, allowing fire suppression agents to enter and extinguish the fire.

3. Convenient Access: The threshold-free design allows easy movement of carts and other transport tools in and out of the channel without obstruction.

4. Aesthetic Appeal: The channel features transparent glass windows and a cold-rolled steel exterior that matches the cabinets. This design offers high strength, good visibility, and a visually pleasing look that complements the server room.

5. Customizable Options: The closure system can be adjusted based on the height of the cabinets and the available ceiling space. Users can choose between sliding or side-opening doors depending on the width of the external walkway.

6.Reliable Installation: All components are securely attached to the load-bearing frame of the cabinets. The fixing points are located on the top, front, and sides of the frame for added stability.

Hot Air Channel System Components

The hot air channel system includes the following components: End doors , Aluminum profile frame modules,Sunlight panels, Cable trays (including cable management modules) , Touch display screens ,Temperature and humidity collection systems , Access control systems , Sound and light alarm systems , Intelligent color lighting systems

Installation Methods

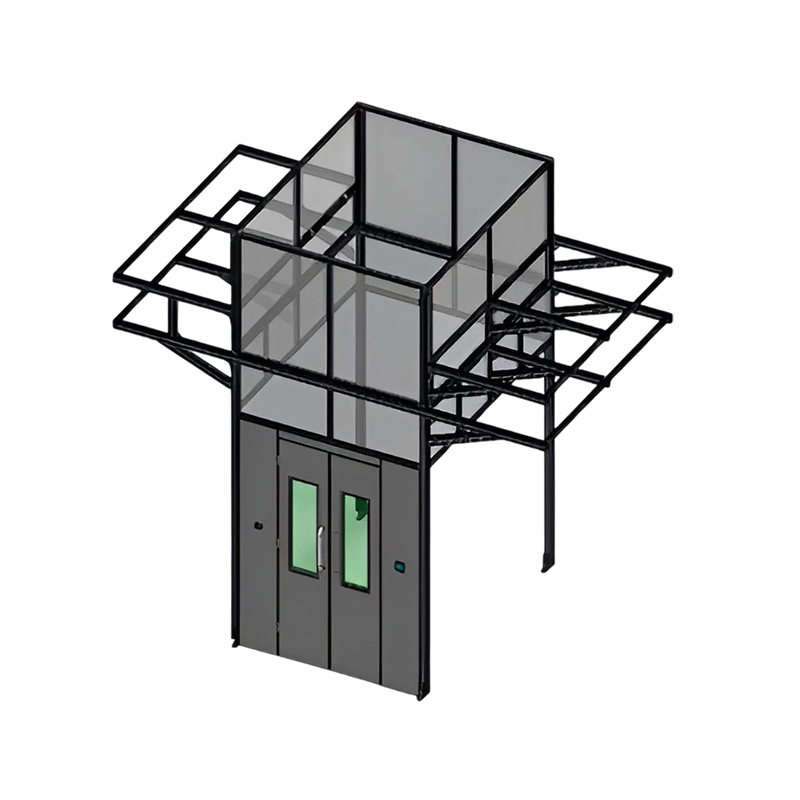

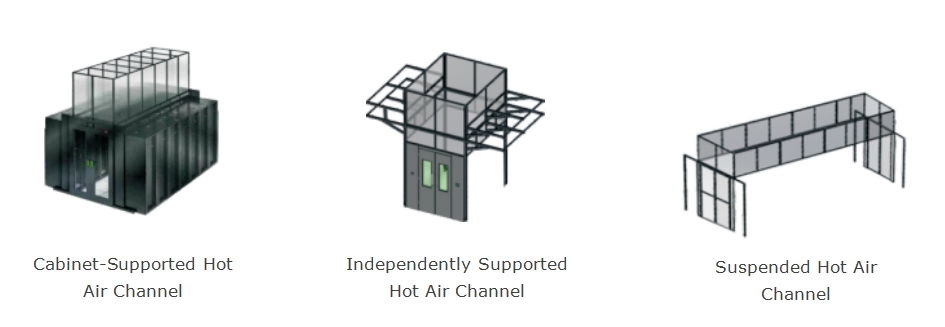

The hot air channel can be installed in the following ways: Supported by the cabinets , Independently supported by aluminum profiles , Suspended using aluminum profiles

Product Structure

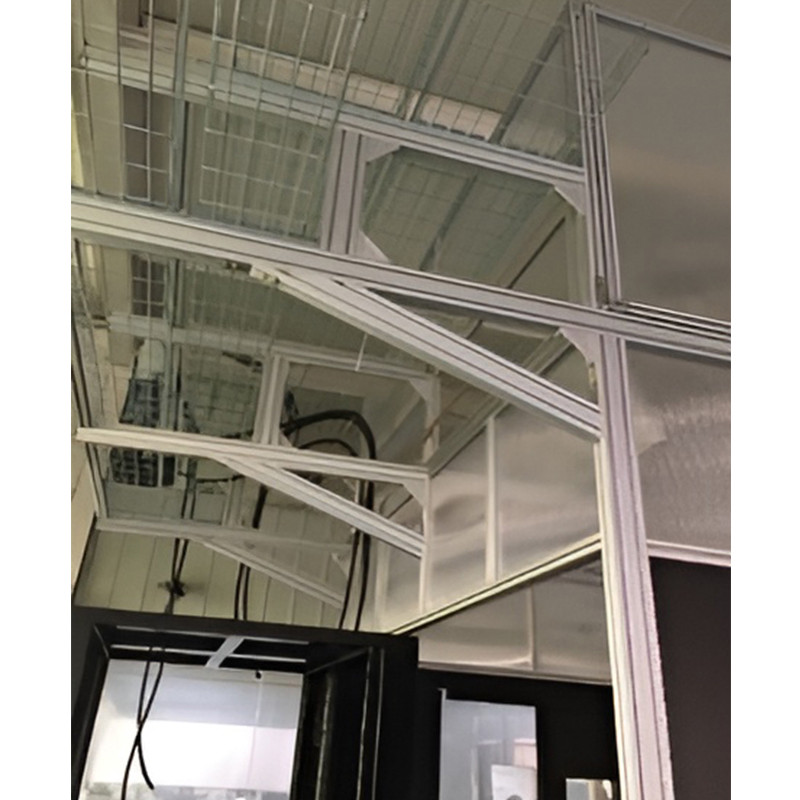

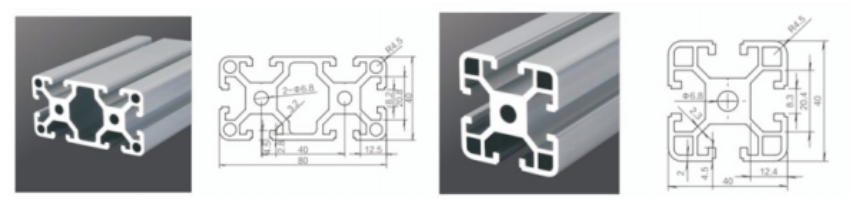

The aluminum alloy frame is made from material that meets European standards. The enclosure components of the hot air channel are independent supports, eliminating the need for rack support, and can adapt to fit on top of switch frames. The main support can be finished in anodized black to match the rack and easily modified with compatible accessories. The structural supports are prefabricated from aluminum profiles into modular sections for straightforward on-site assembly.

The height of the channel closure accommodates cabinets from 2150 mm to 2550 mm, with a width of 600 mm, suitable for various cabinet sizes.

All frame panels are made from fire-resistant polycarbonate, with over 80% light transmittance, and are installed using a snap-fit method for easy removal. The supports can be installed on the floor or anchored with expansion bolts.

The interior of the structure has pre-drilled locations for cameras, lighting, and other equipment, with additional openings for pressure sensors, smoke detectors, and temperature probes.

Product Features

1.Climate Adaptation: The system employs a closed hot air channel with a ceiling return and diffuse supply. Supply temperature is set at 22°C, while return temperature reaches 34°C. This setup can increase the chilled water supply/return temperature to 17–23°C, allowing for an extended period of free cooling. Approximately 81% of the year, the chiller units can remain off. The elevated water temperature boosts the system's COP to 7.0, significantly reducing energy consumption.

2.Improved Temperature Control: Traditional closed cold aisle temperatures range from 28–30°C. With this hot air channel system, the temperature inside the channel reaches about 34°C, while the surrounding server room remains cool, not exceeding 24°C. This environment is more comfortable for maintenance personnel.

3. Height Requirements: Compared to traditional closed cold aisles, this system requires a slightly higher ceiling height. Careful calculation of total height is essential for multi-story buildings. The ends of the profiles can be fitted with rubber caps.

The ends of the profiles can be fitted with rubber caps.