1. Production Introduction

The data center's enclosed channel system achieves energy efficiency by sealing off the cold/hot channels, effectively addressing the high energy consumption of traditional data center cooling systems. With the same cooling effect, the closed cold channel reduces the indoor air conditioning fan speed from 100% to 30%, resulting in a 90% reduction in fan power consumption. This reduced fan speed slows the airflow, allowing it to absorb more heat and raising the return air temperature to 37°C.

Additionally, the airflow temperature is lower than that of the air conditioning system, and the temperature under the raised floor approaches the server inlet temperature, creating a minimal temperature gradient.

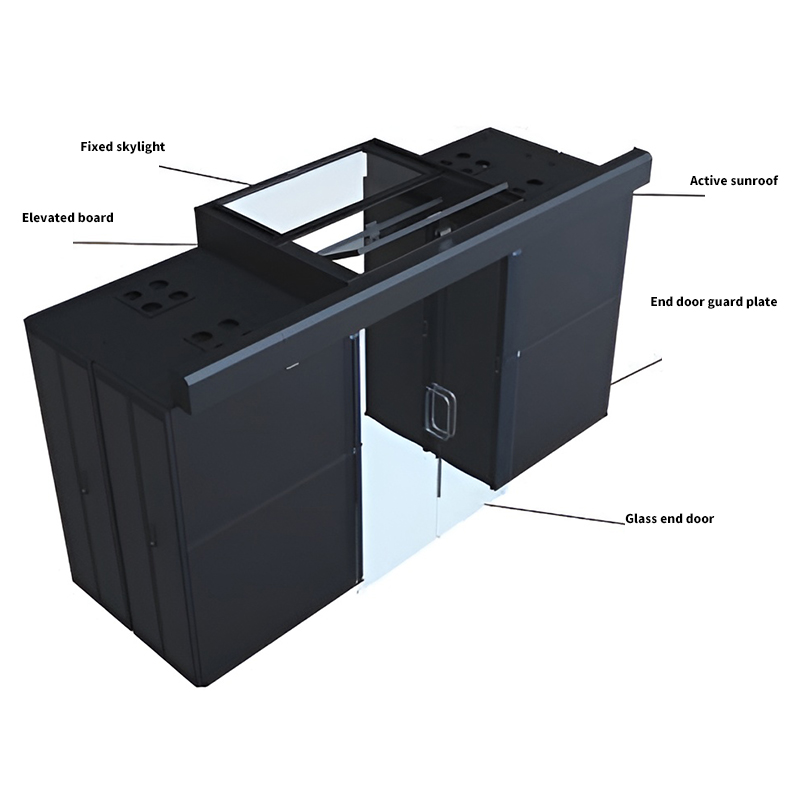

The closed cold channel operates on the principle of separating hot and cold air. Cold air enters the enclosed channel, where equipment at the front of the cabinet draws in the cold air. After cooling, the hot air is discharged from the back of the cabinet into the hot channel, quickly returning to the air conditioning return air outlet. This closed channel system integrates with the cabinet and consists of an end door and a top panel.

The channel end door is constructed from frameless explosion-proof tempered glass, providing good impact resistance and high light transmittance while maintaining an elegant, minimalist design. The top panel includes a fixed panel, a flip panel, and a functional panel, forming an integrated skylight when closed, which enhances light transmission and comfort. The functional top panel also offers space for sensor installation, supporting intelligent monitoring of the channel system.

2. Top Skylights

2.1 The top of the cold air channel features a flat skylight that is fully enclosed and made of transparent material, with light transmission exceeding 85% of the skylight area, eliminating the need for additional lighting.

2.2 The enclosed top of the cold air channel consists of fixed skylights, movable skylights, and other sheet metal accessories.

2.3 The skylights at both ends of the cold air channel near the door are fixed. Between each fixed skylight, there is a movable skylight. If two movable skylights are adjacent, one should be removed to add a fixed skylight, ensuring that there is a fixed skylight between any two movable skylights.

2.4. Skylight dimensions: the width matches the cabinet width, and the length corresponds to the channel width.

2.5 Skylight materials: colorless, transparent tempered glass (t = 5.0mm) with a metal frame; they are removable for easy cleaning.

2.6 Skylight placement: A. The skylight can be placed directly on top of the cabinet. B. Alternatively, it can be placed on a raised panel above the cabinet. The choice between these two methods depends on whether the lower edge of the movable skylight cover is more than the average height of personnel. If it is higher, it ensures safety without hindering personnel working in the data center channel. If it is lower, a raised panel (200-300mm) should be installed on top of the cabinet to meet safety working conditions.

3. Fire Alarm Linkage

3.1 The movable skylight is equipped with an automatic opening function linked to the fire alarm system.

3.2 There are two forms of fire alarm linkage:

A. Power-Off Opening

B. Power-On Opening

A. Power-Off Opening: This system consists of a movable skylight and a magnetic lock.

Operation Mode: Under normal conditions, the movable skylight is held in place by the energized magnetic lock, keeping the skylight panel parallel to the channel. In the event of a fire alarm that results in power loss to the equipment room, the magnetic lock loses its power and suction, causing the skylight glass to open automatically due to gravity. Once the fire suppression system is activated, extinguishing agents enter the enclosed cold channel space through the opened skylight. After the fire is extinguished, the skylight must be manually pushed up to close it.

Power Supply Method for the Movable Skylight Magnetic Lock:

a. Each cold channel connects a power line (220V) from the equipment room, which is then stepped down to 12V/24V and connected to the magnetic lock of each skylight.

b. Each cold channel pulls a separate power line (220V), also stepped down to 12V/24V, which connects to the magnetic lock of each skylight. This power line is designated as the mandatory power supply for fire safety shutdowns.

In both power supply methods, the magnetic lock for the movable skylight continuously operates in an energized state.

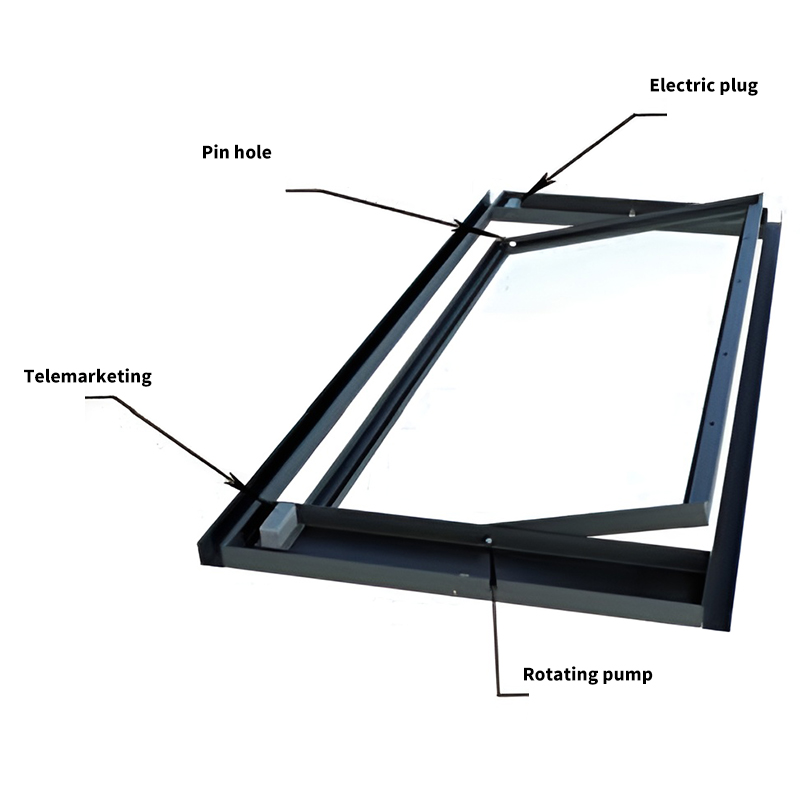

B. Power-On Opening: This system consists of a movable skylight, two electric locks, a power control box, and other components. (Patent application in progress)

Operation Mode: Under normal conditions, the movable skylight operates under power-off status, with the electric locks’ locking pins inserted into the side holes. The skylight panel remains parallel to the channel. When a fire alarm occurs, the monitoring room sends a dry contact signal, which is received by the signal control box. The electric locks are powered on to retract the locking pins on both sides, causing the skylight glass to open automatically. Once the fire suppression system is activated, extinguishing agents enter the enclosed cold channel space through the opened skylight. After the dry

contact signal is cut off, the locking pins pop out, and after the fire is extinguished, the skylight must be manually pushed up to close it.

Power Supply Method for the Movable Skylight Electric Locks: Each cold channel connects a power line (220V)

from the equipment room to the power control box, and the output power line (24V) connects to the electric locks of

each movable skylight. In this power supply method, the electric locks of the movable skylight operate continuously

in a power-off state, ensuring energy efficiency and environmental protection.

4. Channel Doors

Channel doors can be selected from manual double-opening doors, manual sliding doors, and electric sliding doors.

4.1 Manual Double-Opening Door: Includes hinges, door closer, glass (5mm tempered glass), and iron frame, along with end door sealing brush and vertical sealing strips in the middle.

4.2 Manual Sliding Door A: Includes a guide rail, fully glass (12mm tempered glass) that slides left and right, with an end door sealing brush and vertical sealing strips in the middle.

4.3 Manual Sliding Door B: Includes a guide rail, glass (5mm tempered glass) + iron frame, sliding left and right, with an end door sealing brush and vertical sealing strips in the middle. The manual sliding door can be equipped with a damping system that automatically closes the door after it is opened.

4.4 Electric Sliding Door A: Sliding glass door (12mm tempered glass) equipped with access control, exit switch, and includes an end door sealing brush and vertical sealing strips in the middle.

4.5 Electric Sliding Door B: Glass (5mm tempered glass) + iron frame, equipped with access control, exit switch, and includes an end door sealing brush and vertical sealing strips in the middle. The door header can be equipped with LED lights based on requirements, which can be set to remain lit when the door is open or closed.