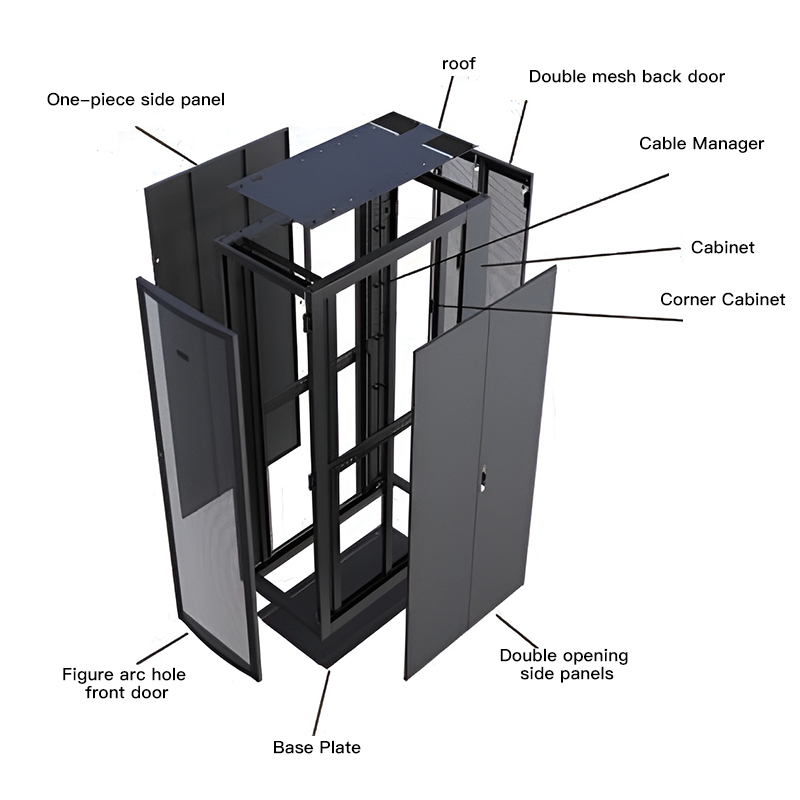

Data Center Server Cabinet

Taking Exquisite Design as Our Essence, Precision Manufacturing as Our Foundation

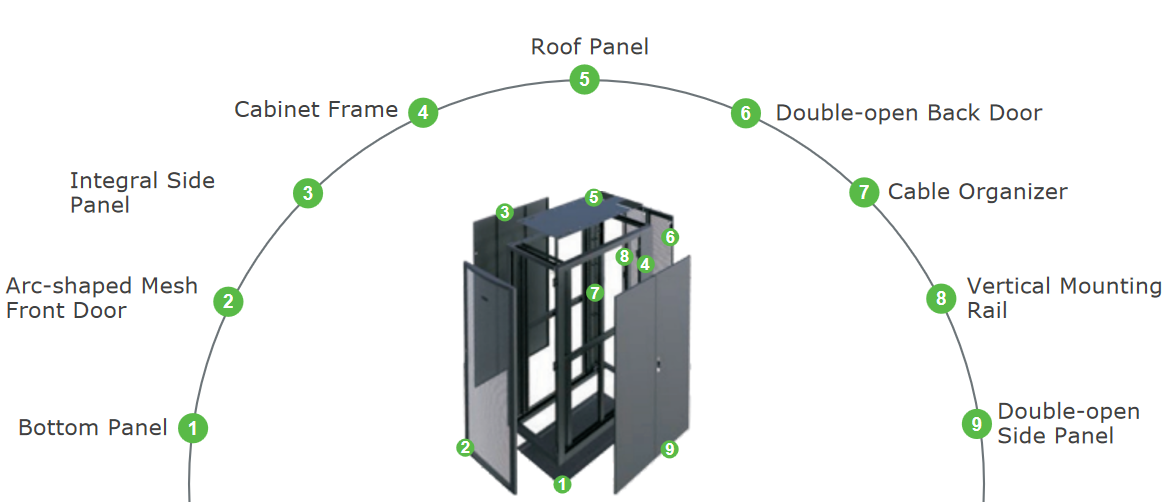

Boersida cabinets are independently developed to meet international standards, featuring 42 internal expansion spaces. They utilize an industry-leading aluminum-magnesium alloy composite profile structure, ensuring high strength, lightweight durability, and easy installation and maintenance.

The product design embodies Dawning Information Industry Co., Ltd.'s commitment to "advanced, cutting-edge, high-end" aesthetics. Integrated with sophisticated LED lighting technology, the cabinets exude a modern, technological flair, showcasing Dawning Information's innovative and high-quality approach to professional product design.